Well pump pressure switches operate by turning the pump on and off in response to pressure increases or decreases. The main purpose of well pump pressure switches, also known as well tank pressure switches or water well pressure switches, is to make sure that the piping system within the home, warehouse, or business facility is at a high enough pressure to be able to supply water, but not too high. Read More…

Tecmark is a designer and manufacturer of remotely actuated controls used by OEMs worldwide. We offer an extensive line of high pressure switches, and our customer service representatives will help you find the perfect model for your application. Whether you are looking for an in-house solution, or an industry need, we continue to develop technological advancements.

For over 35 years, MPL has specialized in unique miniature pressure switch solutions to the world’s leading manufacturers. MPL pressure sensors and switches can be found in the most demanding environments from automotive to health care where long-life, reliable solutions are required. Visit our website for details.

At Emerson Automation Solutions, we are dedicated to helping industries operate more safely, efficiently, and sustainably through innovative automation technologies. We design and manufacture advanced pressure switches that serve as critical components in monitoring and controlling industrial processes.

Ashcroft® manufactures a full line of high quality pressure switches for the shutdown and control of various types of processes. Ashcroft® switches meet application needs for industries such as off-road equipment, generators, compressors and many more. As the leader in technology and innovations, we design our products based on our customer’s requirements.

More Well Pump Pressure Switch Manufacturers

How Well Pump Pressure Switches Work

Well pump pressure switches are essential components in residential and commercial water systems, ensuring a consistent supply of clean water by controlling the operation of well pumps. When evaluating well pumps and pressure switch systems, it's important to understand how these components interact to maintain optimal water pressure for daily use. In simple terms, a pressure switch monitors the water pressure within the system and signals the well pump to turn on or off based on pre-set pressure thresholds.

The set point is the specific pressure value at which the pressure switch activates (closes) or deactivates (opens) the electrical circuit to the pump. Many typical residential pressure switches are rated for pressure ranges such as 30/50 PSI, meaning the pump turns on when pressure drops to 30 PSI and turns off at 50 PSI. This range ensures a stable water flow and protects plumbing fixtures and appliances from damage due to excessive pressure fluctuations.

Key components of a pressure switch include the adjustment screw (for tuning the set point), diaphragm (which reacts to water pressure), lever, spring, and electrical contacts. Adjusting the spring tension changes the pressure threshold, allowing homeowners and professionals to customize their water system's performance.

Pressure switches operate solely based on water pressure. As water is drawn from the well and household demand increases, system pressure drops. When it falls to the lower set point, the diaphragm flexes, engaging the electrical contacts and turning the pump on. As the pump raises water pressure to the upper limit, the diaphragm repositions, breaking the circuit and shutting the pump off. This automatic process enables energy efficiency, reduces pump wear, and maintains reliable water access.

Why Are Well Pump Pressure Switches Important?

Well pump pressure switches are critical for maintaining safe and efficient water delivery. By automating the cycling of the pump, they prevent both dry running (which can damage the pump) and over-pressurization (which can harm plumbing systems). For homeowners and facility managers, a properly functioning pressure switch translates to consistent water pressure at the tap, lower maintenance costs, and longer equipment lifespan.

How Can You Tell If Your Pressure Switch Is Failing?

Are you experiencing inconsistent water pressure, erratic pump cycling, or no water at all? These could be signs of a faulty pressure switch. If you notice issues such as frequent on/off cycles, water leaks around the switch, or visible corrosion, it's time to inspect your system. Understanding the symptoms of pressure switch failure can help you take proactive maintenance steps before a total breakdown occurs.

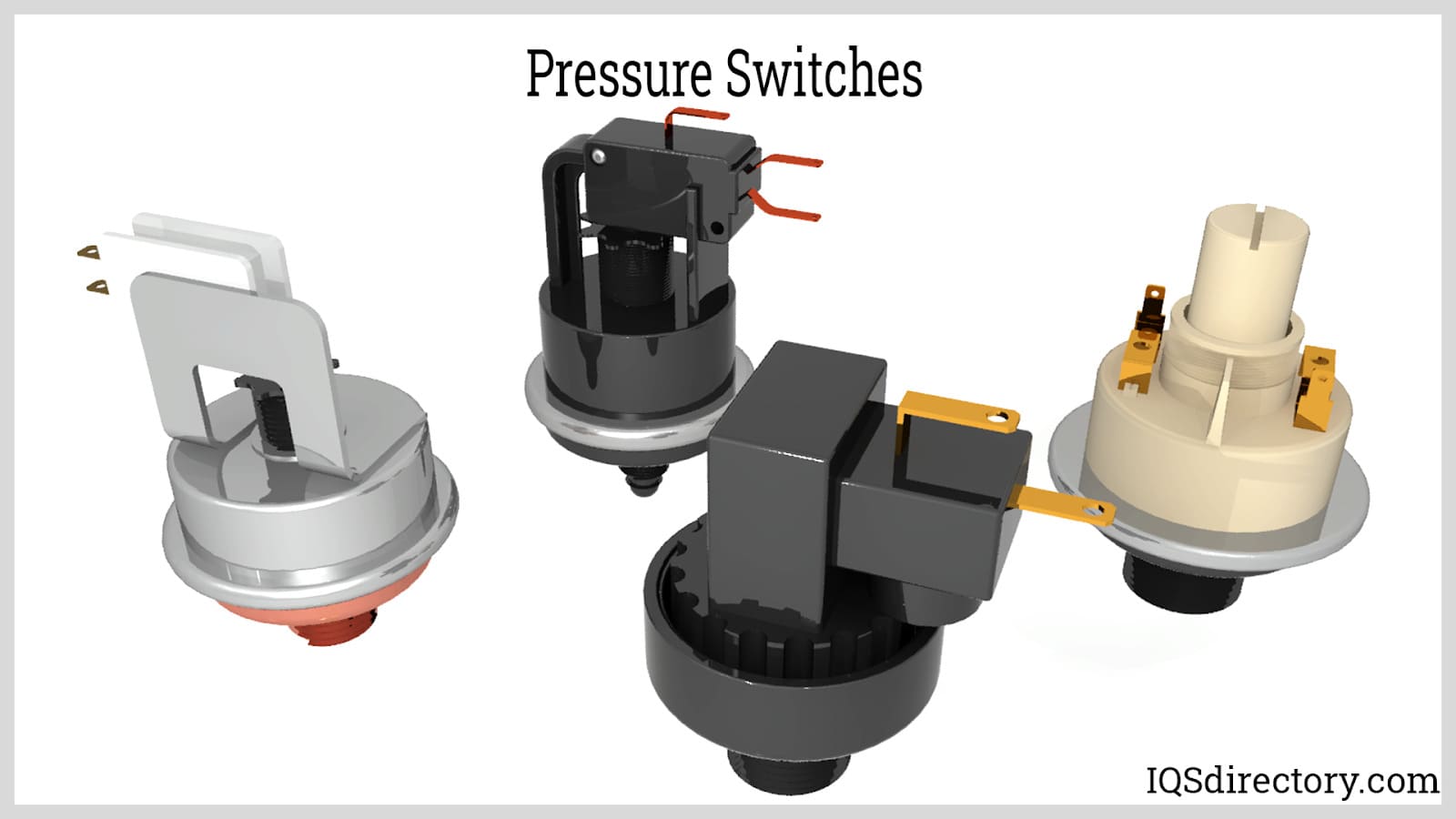

Types of Pressure Switches

Pressure switches come in various designs to suit different system requirements, applications, and industry standards. Choosing the right type of pressure switch is crucial for optimizing system performance, minimizing downtime, and ensuring compatibility with your well pump setup. Below are the primary types of pressure switches used in water well systems and other industrial applications:

Electronic Pressure Switches

Electronic pressure switches use advanced sensing technologies, such as pressure transducers or strain gauges, combined with integrated electronic circuitry. These devices convert pressure readings into electrical signals that can be displayed digitally or transmitted to control systems. Electronic pressure switches offer precise control, fast response times, and programmable features such as:

- Adjustable setpoints for on/off operation

- Local and remote pressure monitoring

- Time delay functions to prevent rapid cycling

- Analog and digital output options for integration with automation systems

These switches are ideal for industrial water systems, advanced well monitoring, HVAC systems, and environments where high accuracy and remote diagnostics are required. Their versatility extends to applications like reverse osmosis, irrigation control, fire protection systems, and process automation.

Mechanical Pressure Switches

Mechanical pressure switches are widely used in residential and light commercial applications due to their simplicity, reliability, and cost-effectiveness. They rely on mechanical elements—such as diaphragms, bellows, or pistons—that physically deform under water pressure, triggering the switch contacts. Mechanical switches are easy to install, require minimal maintenance, and provide long service life in typical well pump systems.

- Common pressure sensing elements include diaphragms, bellows, and Bourdon tubes

- Suitable for basic on/off pump control and most household water systems

- Available in a range of pressure ratings, including popular 20/40, 30/50, and 40/60 PSI models

While they lack advanced programmability, mechanical pressure switches are dependable for traditional well water systems, sprinkler pumps, and booster pump setups.

How to Select Between Electronic and Mechanical Pressure Switches?

Wondering which type of pressure switch is best for your well pump or water system? Consider the following factors:

- System Complexity: Electronic switches excel in complex, automated systems, while mechanical switches are preferred for straightforward, standalone installations.

- Budget: Mechanical switches are cost-effective and sufficient for most home applications; electronic switches, though pricier, add value with advanced features.

- Maintenance: Mechanical switches are serviceable by most homeowners; electronic switches may require professional support for diagnostics and repairs.

- Accuracy Needs: If precise control and monitoring are priorities, electronic models are the clear choice.

Still not sure which pressure switch to choose? Contact a pressure switch specialist to discuss your unique use case, or compare top-rated models from leading manufacturers in our database.

Applications and Use Cases for Well Pump Pressure Switches

Well pump pressure switches are utilized across a broad spectrum of environments, each with its own set of requirements and challenges. Understanding these applications helps buyers and specifiers select the most appropriate switch for their needs.

- Residential Water Supply: Ensures reliable pressure for showers, faucets, dishwashers, and laundry by automatically managing the well pump.

- Agricultural Irrigation: Maintains consistent pressure for sprinklers and drip lines, protecting crops and optimizing water usage.

- Industrial Process Water: Regulates pump operation in manufacturing, cooling towers, and process washdown systems.

- Commercial Buildings: Supports booster pump systems for high-rise water supply and HVAC pressure management.

- Fire Protection Systems: Triggers pumps in fire suppression applications to guarantee adequate pressure when needed.

- Water Treatment Facilities: Controls various pumps in filtration, softening, and reverse osmosis units.

Benefits of Quality Well Pump Pressure Switches

Investing in a high-quality well pump pressure switch delivers a host of advantages for homeowners, businesses, and industrial operators. Here are the key benefits:

- Consistent Water Pressure: Avoids annoying fluctuations, providing steady water flow for all fixtures and appliances.

- Extended Pump Life: Reduces wear and tear by preventing unnecessary cycling and dry running.

- Energy Efficiency: Optimizes pump operation, lowering electricity consumption and utility bills.

- Safety: Prevents hazardous over-pressurization and protects plumbing integrity.

- Low Maintenance: Reliable, durable designs mean fewer service calls and longer intervals between replacements.

- System Automation: Advanced switches enable integration with smart home systems and industrial control networks for remote monitoring and alerts.

If you’re comparing different pressure switch models, be sure to review performance specifications, warranty details, and compatibility with your existing well pump setup.

Common Problems with Well Pump Pressure Switches

Even the best well pump pressure switches can experience issues over time. Understanding these common problems helps you diagnose, maintain, and repair your water system efficiently.

- Water Leakage: If water is dripping from the internal mechanism of the switch or from underneath the housing, consider tightening the plumbing connection by using plumber's pliers to turn the brass fitting in a clockwise direction. If the leakage persists, the pressure switch needs to be changed because it is likely caused by the internal mechanism. Water intrusion can lead to electrical shorts and corrosion, so prompt replacement is critical.

- Bad Contacts: Over time, the pressure switch's electrical contacts may become less reliable. Two major culprits are the switch's power cycling too often and the presence of corrosive materials. File the damaged area away to make a temporary repair to the contacts, but make sure the pump's power is turned off first. It is necessary to replace the switch for a more long-lasting solution. Signs include erratic pump operation, arcing, or visible pitting on the contacts.

- Damaged Diaphragm: Water from the supply exerts pressure against the switch's diaphragm to produce a reading of the pressure. The diaphragm may be unable to detect the proper water pressure if it is old due to wear and tear. It's time to purchase a replacement switch if this happens. Diaphragm failure is often revealed by the pump not switching on or off at the desired pressures.

- Failed Connection: A switch issue could be a sign of trouble elsewhere in the system. For instance, improperly sized pipe may result in a connection that leaks. As a result, the pressure switch won't function properly. Check the pipe to make sure it is the appropriate diameter for the task. Look out for any leaks or indications that the pipe doesn't fit the switch snugly. Improper installation can also cause air leaks and pressure loss, leading to system inefficiency.

When troubleshooting well pump pressure switch problems, always turn off the power at the breaker before inspecting or servicing the switch. If you are unsure about the cause of a malfunction, consider consulting a professional well pump technician or requesting support through our service directory.

Pressure Switch Buying Guide: Key Decision Factors

Choosing the right well pump pressure switch requires careful consideration of system demands, environmental factors, and long-term maintenance goals. Here’s a detailed guide to help you make an informed purchase:

- Pressure Range: Match the switch’s pressure ratings to your pump and plumbing system (common options: 20/40, 30/50, 40/60 PSI).

- Electrical Rating: Ensure compatibility with your pump’s voltage and amperage requirements (common: 115V or 230V systems).

- Switch Type: Decide between mechanical or electronic models based on system complexity and budget.

- Housing Material: Choose corrosion-resistant materials if your well water is high in minerals or chemicals.

- Brand Reputation: Research manufacturers known for quality, reliability, and customer support.

- Certifications: Look for UL, CSA, or other recognized safety standards, especially for commercial or industrial applications.

- Ease of Installation: Some switches feature user-friendly designs for quick retrofits or upgrades.

- Warranty: Consider extended warranty options for peace of mind and long-term value.

Choosing the Proper Well Pump Pressure Switch Manufacturer

To ensure optimal performance and reliability, it is vital to source your well pump pressure switch from a reputable manufacturer. Our well pump pressure switch manufacturer directory makes it easy to compare products, capabilities, and support services from leading brands in the industry. When evaluating suppliers, consider the following:

- Product Range: Does the manufacturer offer a variety of models for different pressure ranges, voltages, and applications?

- Customization: Can they provide custom solutions for unique system requirements or challenging operating conditions?

- Technical Support: Is expert guidance available for selection, installation, and troubleshooting?

- Lead Times: What are typical delivery times for standard and custom orders?

- After-Sales Service: Are replacement parts, extended warranties, and service contracts readily available?

To make sure you have the most productive outcome when purchasing a well pump pressure switch from a well pump pressure switch manufacturer, it is important to compare at least 4 to 5 companies using our list of well pump pressure switch manufacturers. Each manufacturer profile highlights their areas of expertise and capabilities, with a direct contact form for more information or to request a quote. Review each company’s website using our patented website previewer to get an idea of their specialties, and then use our simple RFQ form to contact multiple well pump pressure switch manufacturers with the same request.

Frequently Asked Questions About Well Pump Pressure Switches

- How do I know if my pressure switch is set correctly? Check your switch’s set points (typically marked on the housing) and measure your water system’s pressure using a gauge. Adjust the switch if needed to match your desired cut-in and cut-out pressures.

- Can I replace a pressure switch myself? Many homeowners can replace mechanical switches with basic tools, but always turn off power at the breaker and follow manufacturer safety instructions. Electronic switches may require professional installation.

- How often should I inspect or replace my pressure switch? Inspect your switch annually for signs of wear, corrosion, or leaks. Replacement intervals vary, but most switches last 5–10 years under normal use.

- What causes frequent pump cycling? Frequent cycling can indicate a waterlogged pressure tank, a malfunctioning switch, or plumbing leaks. Diagnose and repair as soon as possible to prevent pump damage.

Next Steps: Optimize Your Water System with the Right Pressure Switch

Whether you’re maintaining a residential well, designing an irrigation system, or managing process water in an industrial setting, selecting the right well pump pressure switch is vital for reliable, efficient performance. By understanding how pressure switches work, the differences between electronic and mechanical models, common problems, and key buying criteria, you can ensure your water system operates at its best.

Ready to take action? Use our pressure switch request form to get personalized quotes, or browse our resource library for installation guides, troubleshooting tips, and expert insights. If you have specific questions or need support, contact our team today for fast, helpful answers.

Don’t leave your water system’s performance to chance—choose a quality pressure switch from a trusted manufacturer and enjoy years of reliable service and peace of mind.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services