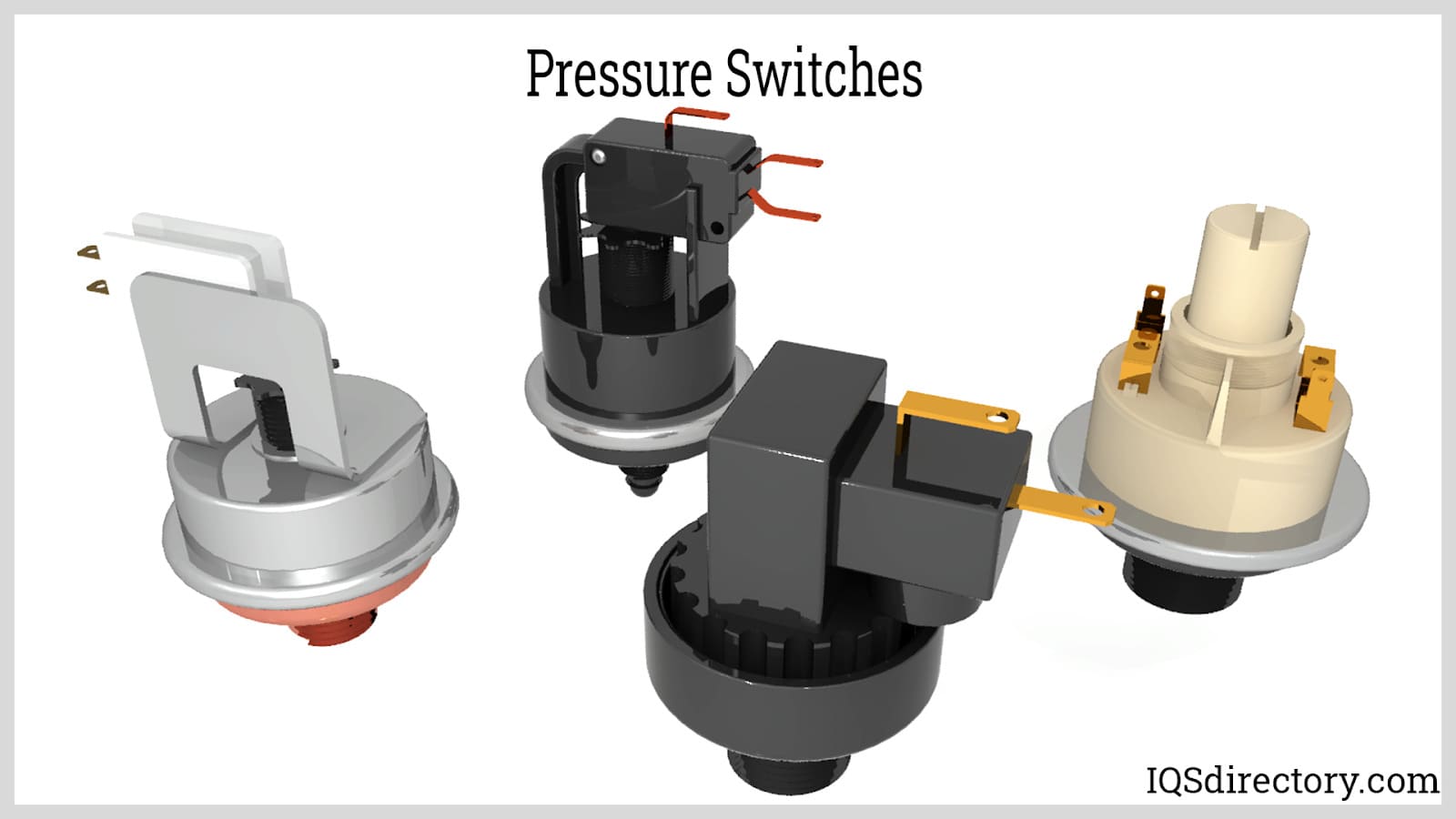

Pressure switches are electrical components all about pressure control. They do so by sensing changes in liquid and/or gas pressure and reacting with a preprogrammed response. Specifically, they open or close when activated at certain pressure points, or actuation points, or in other words, when pressure reaches a predetermined level, whether it be rising or falling, on their input. Read More…

Tecmark is a designer and manufacturer of remotely actuated controls used by OEMs worldwide. We offer an extensive line of high pressure switches, and our customer service representatives will help you find the perfect model for your application. Whether you are looking for an in-house solution, or an industry need, we continue to develop technological advancements.

For over 35 years, MPL has specialized in unique miniature pressure switch solutions to the world’s leading manufacturers. MPL pressure sensors and switches can be found in the most demanding environments from automotive to health care where long-life, reliable solutions are required. Visit our website for details.

At Emerson Automation Solutions, we are dedicated to helping industries operate more safely, efficiently, and sustainably through innovative automation technologies. We design and manufacture advanced pressure switches that serve as critical components in monitoring and controlling industrial processes.

Ashcroft® manufactures a full line of high quality pressure switches for the shutdown and control of various types of processes. Ashcroft® switches meet application needs for industries such as off-road equipment, generators, compressors and many more. As the leader in technology and innovations, we design our products based on our customer’s requirements.

More Pressure Switch Manufacturers

Sometimes, a pressure switch reacts automatically to changes in system pressure, yet in certain scenarios, users may need to manually reset it using a reset button. This manual intervention is typically prompted only after the switch has triggered an alert—such as an alarm, warning light, or other notification—indicating a deviation from preset pressure thresholds. Understanding when and how to reset a pressure switch is essential for maintaining system safety and operational efficiency.

Pressure switches serve indispensable roles across a wide range of industries and applications, from everyday home systems to complex aerospace environments. These devices meticulously regulate flow pressures, making them essential in critical domains such as automotive systems, industrial process manufacturing, petrochemical distribution, wastewater treatment, and the operational control of pipelines, control panels, pumps, turbines, generators, compressors, off-road machinery, furnaces, blowers, filters, and more. Their versatility ensures reliability, safety, and optimal performance in both commercial and industrial environments.

History of Pressure Switches and Pressure Measurement

The evolution of pressure measurement technology dates back centuries. Galileo stands as a pioneer, inventing a water pump in 1594 designed to harness water pressure for agricultural irrigation—a significant milestone in the control and application of fluid pressures. In 1644, Evangelista Torricelli made a groundbreaking discovery while experimenting with a mercury-filled tube submerged in a bowl of mercury. He observed that the mercury would consistently descend 760 mm, a phenomenon he initially described as a vacuum. Unbeknownst to him, Torricelli had uncovered the foundational principles of atmospheric pressure.

Building on Torricelli’s work, Blaise Pascal in 1650 demonstrated that mercury in Torricelli’s tube responded to atmospheric weight, a concept he named pressure. This revelation led scientists and engineers to further investigate air pressure, culminating in Robert Boyle’s 1661 formulation of Boyle’s Law (PV=K), which established the direct relationship between pressure and volume in gases at constant temperature and quantity.

The scientific advancements of the 1500s and 1600s paved the way for 19th-century innovations. In 1843, Lucien Vidie invented the aneroid barometer, which used a spring balance to mechanically amplify pressure changes for atmospheric measurement. In 1849, Eugene Bourdon patented the Bourdon tube pressure gauge, a design that remains integral to modern mechanical and electrochemical pressure switches.

By 1930, the invention of pressure transducers revolutionized pressure measurement by enabling electrical output signals based on sensed pressures. In 1938, engineers at the California Institute of Technology and the Massachusetts Institute of Technology independently developed the bonded strain gauge. E.E. Simmons of Caltech secured the patent, marking a pivotal advancement in pressure sensing technology.

The advent of solid-state pressure switches in the 1980s, combining bonded strain gauge sensors with triac switches, marked a technological breakthrough. Today, modern pressure switches feature advanced digital outputs, integrated displays, and enhanced intuitiveness, supporting increasingly complex applications. As technology continues to evolve, expect future pressure switches to offer even greater accuracy, responsiveness, and adaptability for industrial automation and process control.

Design and Manufacturing of Pressure Switches

Production Process

Pressure switch manufacturers employ a meticulous assembly process to construct reliable and accurate devices. Some pressure switches are designed to generate electrical output signals and may include a programming interface. In such cases, manufacturers can produce switches compatible with various control systems, including PLCs (Programmable Logic Controllers), SCADA systems, and custom automation software. Options include installing an interface that allows operators to input new switch points, integrating logic systems for real-time updates, or pre-programming the unit at the factory for fixed operation. This flexibility ensures compatibility with both legacy and state-of-the-art control infrastructures.

Materials

The choice of material is critical in pressure switch design and performance. Manufacturers select from a wide array of materials to suit specific application requirements, including:

- Cast aluminum – Lightweight and corrosion-resistant, ideal for general industrial applications.

- Brass – Known for its durability and compatibility with water and air systems.

- Acetal and glass-reinforced polyester – Offer chemical resistance and high strength for challenging environments.

- Plated steel and stainless steel – Provide excellent corrosion resistance, making them suitable for harsh or corrosive settings such as chemical processing plants and marine environments.

- Neoprene, polycarbonate, and PVC – Used for applications requiring flexibility, electrical insulation, or additional resistance to chemicals and weather exposure.

Considerations and Customization

When engineering a pressure switch, manufacturers assess several critical factors:

- Cycle rates – The number of actuations per minute or hour, affecting switch lifespan and suitability for high-demand systems.

- Pressure trip points – The precise pressure levels required to activate or deactivate the switch.

- Sensitivity and accuracy – Essential for applications where even slight pressure deviations can impact safety or product quality.

- Adjustability – Options for user or factory-set calibration, supporting both fixed and variable pressure environments.

To meet specific customer needs, manufacturers can customize:

- Number and location of actuation points

- Response time and cycle speed

- Pressure sensing range (from vacuum to high-pressure applications)

- Switching logic and output signals (e.g., SPST, SPDT, DPDT configurations)

- Environmental protection (IP ratings for dust and moisture resistance)

- Durability and cycle endurance for demanding industrial uses

Looking for a solution for a unique application? Contact a pressure switch manufacturer to discuss custom designs tailored to your project requirements.

Features and Operating Principles

Modern pressure switches integrate a sensing element with either an interface protocol for digital systems or a traditional snap-action mechanical switch. The sensing component detects pressure changes and triggers the switch mechanism when thresholds are crossed.

Common sensing technologies include:

- Piezoresistive pressure sensors – Frequently utilized in electronic pressure switches, these sensors convert mechanical pressure into an electrical signal for digital display or control.

- Elastomeric diaphragms – Flexible membranes made from durable polymers that transmit pressure while acting as a barrier to liquids or gases; commonly used for actuation in mechanical switches and valves.

- Pressure transducers – Devices that measure pressure and convert it into an analog or digital signal, often integrated with process monitoring and automation systems.

Other pressure sensing elements include bourdon tubes (for mechanical gauges), capacitive sensors (for high-precision measurement), and resonant sensors (for digital applications).

Types of Pressure Switches and Their Applications

Manufacturers produce a diverse range of pressure switch types to address specific industrial and commercial needs. The most common categories include hydraulic pressure switches, pneumatic pressure switches, high pressure switches, and low pressure switches. Each type is designed to function optimally in particular environments, whether for liquid or gas systems, and for specific pressure ranges.

Key types and their use cases include:

- Hydraulic pressure switches – Designed to monitor and control liquid pressure in automotive systems (e.g., engine oil pressure, brake systems), pool heating, industrial fluid handling, and heavy machinery. Commonly used to trigger warnings, activate safety mechanisms, or automate pump operation.

- Pneumatic pressure switches – Also called gas or air pressure switches, they manage air compressors, HVAC systems, battery charging stations, gas pumps, and even cockpit alarm systems in aircraft. They are vital in ensuring safe operation and energy efficiency in pneumatic-powered equipment.

- High pressure switches – Engineered for demanding applications such as hydraulic presses, fire suppression systems, and process vessels where high-pressure detection and control are critical for safety and compliance.

- Low pressure switches – Used in vacuum systems, leak detection, low-pressure warning systems, and sensitive instrumentation to ensure pressures do not fall below operational thresholds.

Additional specialized types include:

- Oil pressure switches – Monitor engine oil pressure, providing alerts when levels fall below safe limits, preventing catastrophic engine failure.

- Water pressure switches – Maintain water pressure in residential and commercial plumbing, irrigation, and fire suppression systems by activating pumps as needed.

- Well pump pressure switches – Regulate pressure in water well systems, ensuring consistent water supply and protecting pumps from damage.

- Air compressor switches – Control system pressure by turning compressors on or off to maintain desired air levels, optimizing energy use and preventing equipment damage.

- Differential pressure switches – Maintain balance between two pressure points, such as in filter monitoring, HVAC systems, or aircraft cabin pressurization, using gauges calibrated in psi or other units.

- Furnace pressure switches – Ensure safe operation by verifying air intake or fuel supply in heating systems, playing a critical role in residential and commercial furnace safety.

- Ultrasonic level switches – Non-contact sensors ideal for large tanks or environments with extreme temperature and pressure variation; used in chemical storage, wastewater treatment, and food processing.

- Displacer level switches – Utilize buoyancy principles to regulate liquid levels in sumps and tanks; valued for their simplicity, low maintenance, and reliability.

- Vacuum switches – Detect and manage negative pressure changes, ensuring proper operation of vacuum pumps and leak detection systems.

- Pressure sensitive mats – Serve as safety devices or triggers for access control, robotic cell entry, or intrusion detection by emitting signals when weight is applied.

- Diaphragm pressure switches – Rely on the movement of an elastomeric diaphragm to actuate valves or switches, commonly used in solenoid-operated systems.

- Magnetic float switches – Employ magnet-equipped floats inside sealed tubes to detect and signal liquid levels, widely used in industrial tanks and process vessels.

Are you wondering which type of pressure switch is right for your industry or application? Explore our guides on hydraulic, pneumatic, and specialty pressure switches for detailed comparisons and decision criteria.

Advantages and Key Benefits of Pressure Switches

Pressure switches offer a wealth of advantages that make them a preferred choice in numerous industrial and commercial settings. Key benefits include:

- Ease of use – Simple installation, setup, and operation facilitate rapid integration into new or existing systems.

- High accuracy and reliability – Advanced sensing technology ensures precise detection of pressure changes, reducing false alarms and system downtime.

- Versatility – Adaptable to monitor both air and liquid pressures across a vast range of applications, from HVAC systems to oil refineries.

- Customizability – Can be tailored to specific pressure ranges, output types, and environmental requirements.

- Cost savings – Preventing equipment damage, system failures, or unsafe conditions helps minimize repair costs and liability.

- Compliance – Supports adherence to safety and industry standards, helping facilities avoid costly fines or shutdowns.

Want to learn more about the advantages of pressure switches for your industry? Read our in-depth comparison of pressure switch technologies and their impact on operational efficiency.

Accessories and Add-Ons

Enhance the performance and functionality of your pressure switch system with a range of essential accessories, including:

- Pressure gauges – Provide real-time pressure readings for system monitoring and troubleshooting.

- Fittings and connectors – Ensure secure integration into pipes, tanks, or process lines.

- Sensor mounts and brackets – Facilitate stable installation and easy maintenance access.

- Solid-state and delay relays – Allow for advanced switching control and timing functions.

- Audible alarms and visual indicators – Offer immediate notification of pressure anomalies for rapid response.

Need help selecting the right accessories for your pressure switch? Contact our support team or browse our accessory selection guide.

Industry Certifications and Standards

Meeting appropriate pressure switch standards is essential for ensuring safety, compatibility, and regulatory compliance. Key standards include:

- NEMA (National Electrical Manufacturers Association) – Sets US standards for composition, safety, tolerances, environmental protection, and performance, especially for electric pressure switches.

- CE (Conformité Européene) – Required for products sold in Europe, certifying conformity with EU safety and environmental directives.

- IP (Ingress Protection) ratings – Indicate resistance to dust and moisture, critical for outdoor or harsh environment installations.

- UL (Underwriters Laboratories) – Assures compliance with North American safety standards for electrical equipment.

How do you know which certification your application requires? Consult with industry experts or review our compliance checklist for detailed guidance.

How to Select the Right Pressure Switch Manufacturer

Choosing a reputable pressure switch manufacturer is crucial for obtaining reliable, high-performance products that meet your specific application needs. Here’s a step-by-step approach to ensure you make an informed selection:

- Define your requirements – Identify pressure range, electrical output, environmental conditions, and required certifications.

- Research manufacturers – Use our directory of pressure switch suppliers to compare capabilities, product lines, and customer reviews.

- Select a shortlist – Choose three to four manufacturers that align well with your needs and offer the features you require.

- Contact and consult – Reach out to each manufacturer to discuss your project, customization options, budget, and delivery timelines.

- Request technical documentation – Review datasheets, installation guides, and compliance certifications to confirm product suitability.

- Evaluate customer support – Assess each provider’s responsiveness, technical expertise, and after-sales support.

- Compare and decide – Weigh your options based on product quality, price, lead time, and customer service. Choose the manufacturer that delivers the best overall value and meets your operational goals.

Ready to take the next step? Request a quote from leading pressure switch manufacturers or browse our comprehensive listings to find the ideal partner for your project.

Frequently Asked Questions About Pressure Switches

- What is a pressure switch and how does it work? – A pressure switch is a device that detects changes in pressure and activates a switch when a preset threshold is reached. It can be used to control pumps, signal alarms, or automate processes.

- What are the main differences between mechanical and electronic pressure switches? – Mechanical pressure switches rely on moving parts and physical pressure changes for actuation, while electronic switches use sensors to convert pressure into electrical signals for more precise and programmable control.

- How do I choose the right pressure switch for my application? – Consider factors such as pressure range, media compatibility, environment, switching logic, output type, and certification requirements. Consult with manufacturers for expert guidance.

- How often should pressure switches be tested or calibrated? – The recommended interval varies by application and industry standards, but regular inspection and calibration are vital for maintaining accuracy and reliability.

- Can pressure switches be used in hazardous locations? – Yes, but only if they are designed and certified for use in explosive or corrosive environments (e.g., ATEX, IECEx, or UL hazardous location ratings).

Further Resources and Next Steps

To deepen your understanding of pressure switch technology, explore our in-depth articles and application guides:

- Hydraulic Pressure Switch Selection Guide

- High Pressure Switches: Industrial Applications and Safety Tips

- Oil Pressure Switches: How They Protect Your Engine

- Differential Pressure Switches: Balancing Systems for Peak Performance

Still have questions? Contact our technical support team or request a custom pressure switch quote tailored to your unique requirements.

For more listings and to compare top-rated pressure switch suppliers, visit our Pressure Switch Manufacturer Directory.

By understanding the fundamentals, applications, and decision factors surrounding pressure switches, you can make informed choices that enhance system safety, reliability, and efficiency—no matter your industry or operational challenge.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services