Electronic water pressure switches are used to start and stop the electric water pump automatically based on preset pressures. The water pressure switches not only automate the pumps but also prevent dry running. Most often used in connection with pumps, water pressure switches are capable of monitoring and regulating water pressure systems by engaging the pump unit when the pressure is too low and stopping the pump when the pressure is optimal. Read More…

Tecmark is a designer and manufacturer of remotely actuated controls used by OEMs worldwide. We offer an extensive line of high pressure switches, and our customer service representatives will help you find the perfect model for your application. Whether you are looking for an in-house solution, or an industry need, we continue to develop technological advancements.

For over 35 years, MPL has specialized in unique miniature pressure switch solutions to the world’s leading manufacturers. MPL pressure sensors and switches can be found in the most demanding environments from automotive to health care where long-life, reliable solutions are required. Visit our website for details.

At Emerson Automation Solutions, we are dedicated to helping industries operate more safely, efficiently, and sustainably through innovative automation technologies. We design and manufacture advanced pressure switches that serve as critical components in monitoring and controlling industrial processes.

Ashcroft® manufactures a full line of high quality pressure switches for the shutdown and control of various types of processes. Ashcroft® switches meet application needs for industries such as off-road equipment, generators, compressors and many more. As the leader in technology and innovations, we design our products based on our customer’s requirements.

More Water Pressure Switch Manufacturers

How Water Pressure Switches Operate

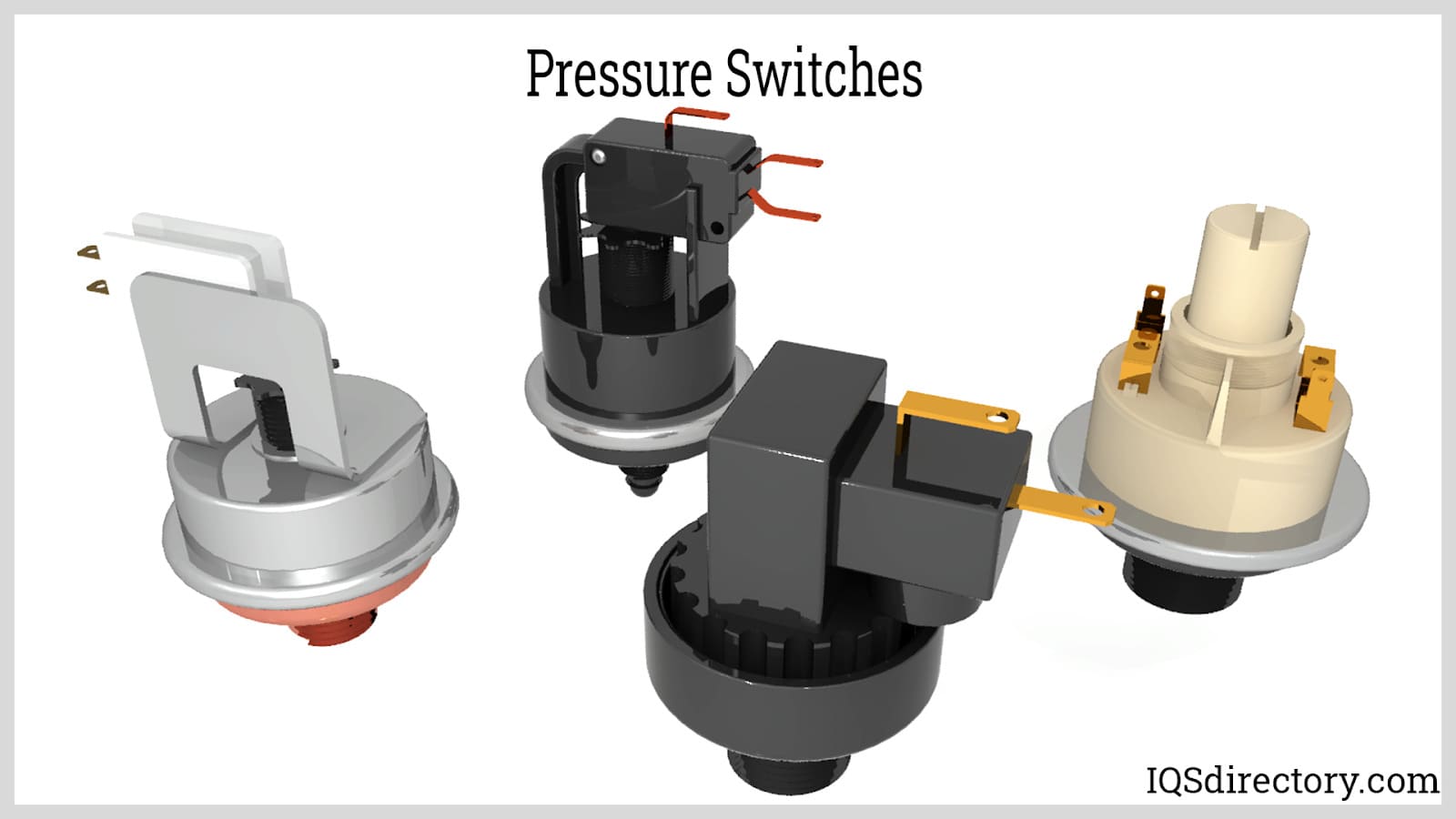

Water pressure switches are essential components in a wide range of industrial and residential water systems, providing automated control and safety functions that keep operations running smoothly. Their core principle is similar to that of other pressure switches: a pressure-sensitive element—such as a piston, diaphragm, Bourdon tube, or bellows—detects the force of pressurized water. This component acts as a transducer, converting the mechanical strain from water pressure into an electrical signal or mechanical action as a function of the applied pressure. This signal can then be used to activate or deactivate pumps, valves, alarms, or other control devices, ensuring that water systems remain within safe operating parameters.

Water pressure switches are programmed to operate at specific actuation points along the pressure spectrum, making them highly versatile for different applications. Depending on the specific requirements of your water system—such as the pressure range, environmental conditions, and compatibility with process fluids—pressure switches can be manufactured using a variety of materials. Common materials include acetal, brass, silicon, bonded metal foil, ceramic, polycarbonate, plated steel, glass-reinforced polyester, polyvinyl chloride (PVC), and cast aluminum. The choice of material is critical to ensure durability, chemical resistance, and optimal performance in various water-based environments.

These switches are ideal for a diverse range of water system applications, including but not limited to:

- Water filtration and purification systems

- Wastewater treatment plants

- Hydraulic circuits and pressurized pipelines

- Sump pumps and booster pump systems

- Swimming pool and spa equipment

- Irrigation and agricultural water control

- Fire suppression and sprinkler systems

- Residential and commercial plumbing setups

In any context where measuring and controlling water flow and pressure is essential, water pressure switches play a pivotal role. They are specifically designed to provide alerts, enable automatic shutdowns, and maintain precise control over a variety of equipment and processes. With advances in pressure switch technology, modern water pressure switches now offer exceptional accuracy, reliability, and long service life, making them indispensable for ensuring the safety and efficiency of pressurized water systems.

Key Benefits of Water Pressure Switches

- Automated Control: Seamlessly automate pumps, valves, and alarms based on real-time water pressure readings.

- System Protection: Prevent damage to equipment by shutting down systems that exceed safe pressure limits.

- Energy Efficiency: Optimize pump operation and reduce energy consumption by maintaining ideal pressure levels.

- Process Reliability: Enhance the reliability and consistency of water distribution and treatment processes.

- Easy Integration: Compatible with a wide variety of control systems, PLCs, and industrial automation solutions.

Factors to Consider When Selecting a Water Pressure Switch

When searching for the best water pressure switch for your application, consider the following key criteria:

- Pressure Range: Ensure the switch operates reliably within the required minimum and maximum pressure limits for your system.

- Electrical Output: Choose between different output types, such as SPST, SPDT, or DPDT, based on your control circuitry needs.

- Accuracy and Repeatability: Look for switches with low hysteresis and high repeatability for precise control.

- Gauge Type: Decide between gauge, absolute, or differential pressure measurement, depending on your monitoring requirements.

- Temperature Rating: Verify compatibility with process fluid temperatures and environmental conditions.

- Material Compatibility: Select diaphragm and housing materials resistant to corrosion, chemicals, and contaminants present in the water.

- Field Adjustability: Opt for switches that allow on-site setpoint adjustment for flexible operation and maintenance.

- Certifications and Ratings: Consider IP, NEMA, and ATEX ratings for protection against dust, moisture, and hazardous environments.

Parts of a Pressure Switch

Understanding the main components of a water pressure switch can help you make informed decisions about maintenance, troubleshooting, and selection. Below is a breakdown of the primary parts found in most mechanical and electronic water pressure switches:

Inlet Port: The inlet port connects the pressure switch assembly to the process unit, serving as the interface where pressurized water enters the switch. Pressure switches are typically fitted to the nozzles on tanks or pipes using threaded fittings, which are industry standard for secure and leak-free connections. In some high-pressure or specialty applications, bolted or welded connectors may be used. It's vital to match the fitting type and pressure rating to the fluid's operating pressure to ensure safety and performance.

Pressure-Sensing Element: The pressure sensor component—such as a diaphragm or piston—is the heart of the switch. It is mechanically actuated by the fluid pressure and designed to transfer sufficient force for reliable operation. The sensitivity and range of the switch are determined by the area of this component exposed to the fluid. As the fluid pressure increases, the actuating force must overcome the resistance of the internal spring.

Spring: The internal spring balances the force generated by water pressure. Preloaded to match the desired operational pressure, the spring ensures the switch only activates when the fluid pressure exceeds or drops below set limits. Spring-based designs allow for consistent actuation points, critical for maintaining process stability.

Differential: This mechanism adjusts the switch's operating pressure range, providing flexibility for high and low setpoints. A set of springs and adjustment screws—often smaller than the main setpoint adjustment—enable fine-tuning. In pumping systems, adjusting the differential screw changes only one end (either high or low) of the pressure range, allowing for customized control strategies.

Setpoint Screw: The setpoint adjustment screw is integrated with the spring mechanism, allowing users to alter the activation pressure. Turning the screw modifies the compression of the spring, enabling precise setpoint calibration for different system requirements.

Switch Housing: The external housing protects internal components from environmental hazards such as dust, moisture, and mechanical impact. The housing's protection rating (IP, NEMA, ATEX) is crucial for selecting a switch suitable for harsh or hazardous locations. For example, NEMA-rated enclosures are common in industrial environments, while ATEX-rated housings are essential for explosive atmospheres.

Diaphragm: The diaphragm, often made from flexible metals, polymers, or elastomers, isolates the switch's internals from the process fluid. Selecting the right diaphragm material is essential for compatibility with the process fluid's chemical composition and temperature.

Contacts: The switch contacts are conductive elements that open or close the electrical circuit based on pressure changes. Made from materials such as copper, silver, gold, or brass, these contacts must offer both excellent conductivity and corrosion resistance. Pressure switches may employ NO (normally open), NC (normally closed), or CO (change-over) contacts. NO contacts are open until the setpoint is reached, activating the circuit, while NC contacts are closed until pressure drops below the setpoint. CO contacts provide both functions for complex control systems.

Electronic vs Mechanical Water Pressure Switches: Which Is Right for You?

When evaluating water pressure switches, you may encounter both mechanical and electronic designs. Mechanical pressure switches use physical elements like springs and diaphragms for actuation, making them simple, durable, and cost-effective. Electronic pressure switches, on the other hand, use sensors and microprocessors to provide precise digital readouts, advanced diagnostics, and programmable setpoints. If your application requires high accuracy, data logging, or integration with digital control systems, electronic models may be the ideal solution. For basic pump control or low-maintenance environments, mechanical switches offer proven reliability.

Choosing the Right Water Pressure Switch Manufacturer

Selecting a reliable water pressure switch manufacturer is crucial to ensuring system longevity, safety, and regulatory compliance. With numerous suppliers and OEMs in the market, it’s essential to carefully evaluate your options. Here are practical steps and decision factors to help you make an informed choice:

- Use a Water Pressure Switch Directory: Start by comparing at least four reputable manufacturers using our water pressure switch directory. Each manufacturer profile highlights their core competencies, certifications, and application focus.

- Review Experience and Capabilities: Visit each manufacturer's business profile page to assess their areas of expertise—such as custom design, OEM integration, or specific industry certifications (e.g., NSF, UL, CE, ATEX).

- Request Quotes and Information: Take advantage of direct contact forms to request more information or a quote tailored to your project requirements. Clearly specify your application, operating conditions, required certifications, and quantity needs.

- Use the Website Previewer: Our patented website previewer lets you quickly scan each manufacturer’s site, helping you identify their specialties, case studies, and customer testimonials.

- Submit a Unified RFQ: Use our simple RFQ form to reach out to multiple water pressure switch manufacturers simultaneously, making it easier to compare pricing, lead times, and support.

Essential Questions to Ask Water Pressure Switch Suppliers

- What is your experience with similar water system applications (e.g., municipal water, industrial processing, residential plumbing)?

- Can you provide references or case studies for comparable projects?

- What certifications and quality standards do your products meet?

- What are your standard and custom lead times?

- Do you offer technical support, installation guidance, or on-site commissioning?

- How do you handle warranty claims or product failures?

- Can you accommodate special requests, such as unique materials or integrated sensors?

Benefits of Partnering with a Trusted Water Pressure Switch Manufacturer

- Product Reliability: High-quality manufacturing reduces downtime and extends service intervals.

- Compliance Assurance: Certified switches ensure adherence to industry regulations and safety codes.

- Expert Support: Access to technical expertise for installation, troubleshooting, and optimization.

- Customization: Ability to tailor switches for unique process requirements or challenging environments.

- Long-Term Value: Reliable switches lower the total cost of ownership through fewer replacements and repairs.

Ready to connect with top water pressure switch manufacturers? Browse our supplier directory now or request a custom quote for your application.

Frequently Asked Questions About Water Pressure Switches

How do I install a water pressure switch?

Installation typically involves mounting the switch to a compatible process fitting (usually threaded), connecting the electrical wires according to the wiring diagram, and adjusting the setpoint using the built-in screw. Always follow the manufacturer’s installation instructions and safety precautions.

What are common water pressure switch failure symptoms?

Signs of a failing pressure switch include inconsistent pump cycling, failure to shut off or turn on at the desired pressure, visible corrosion, water leaks around the housing, or erratic electrical signals. Regular inspection and preventive maintenance can help avoid costly downtime.

Can water pressure switches be used with aggressive or corrosive fluids?

Yes, but you must select switches with diaphragms, seals, and housings made from materials compatible with the process fluid. For corrosive or high-temperature applications, consult manufacturers for suitable options such as stainless steel, PTFE, or specialized elastomers.

What maintenance do water pressure switches require?

Routine maintenance includes checking for leaks, ensuring electrical connections are secure, inspecting diaphragm and spring integrity, and recalibrating the setpoint as needed. For critical or continuous-duty systems, schedule periodic professional inspections to maximize switch lifespan and reliability.

How do I troubleshoot a water pressure switch?

Begin by isolating the switch and verifying that the supply voltage and process pressure are within specifications. Inspect the diaphragm, spring, and contacts for wear or contamination. Use a multimeter to check continuity across the contacts.

Industry Trends and Innovations in Water Pressure Switches

The water pressure switch market is evolving rapidly, driven by advancements in smart control systems, IoT-enabled monitoring, and stricter environmental regulations. Modern switches now offer features such as digital displays, remote monitoring, wireless connectivity, and integration with building management systems (BMS). These innovations improve operational visibility, allow predictive maintenance, and facilitate compliance with water conservation initiatives.

Emerging Use Cases

- Smart Cities: Networked pressure monitors help municipal utilities detect leaks, optimize pumping station efficiency, and reduce water waste.

- Industrial Automation: Integration with PLCs and SCADA systems delivers real-time process data and automated responses to pressure changes.

- Remote Infrastructure: Wireless-enabled pressure switches support monitoring of rural or hard-to-reach water assets.

Conclusion: Making the Right Water Pressure Switch Choice

Water pressure switches are indispensable for managing, protecting, and optimizing water systems across diverse industries. By understanding their operating principles, key components, and selection criteria, you can ensure reliable performance and long-term value. Whether you’re outfitting a new installation, upgrading an aging system, or seeking to enhance operational intelligence with smart pressure switches, choosing the right product and manufacturer is essential.

Need help with selection or technical questions? Contact our water pressure switch experts for personalized advice and solutions tailored to your unique requirements.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services